Reasons and Elimination of Noise of Low-Voltage Powered Rail Pallet Trucks

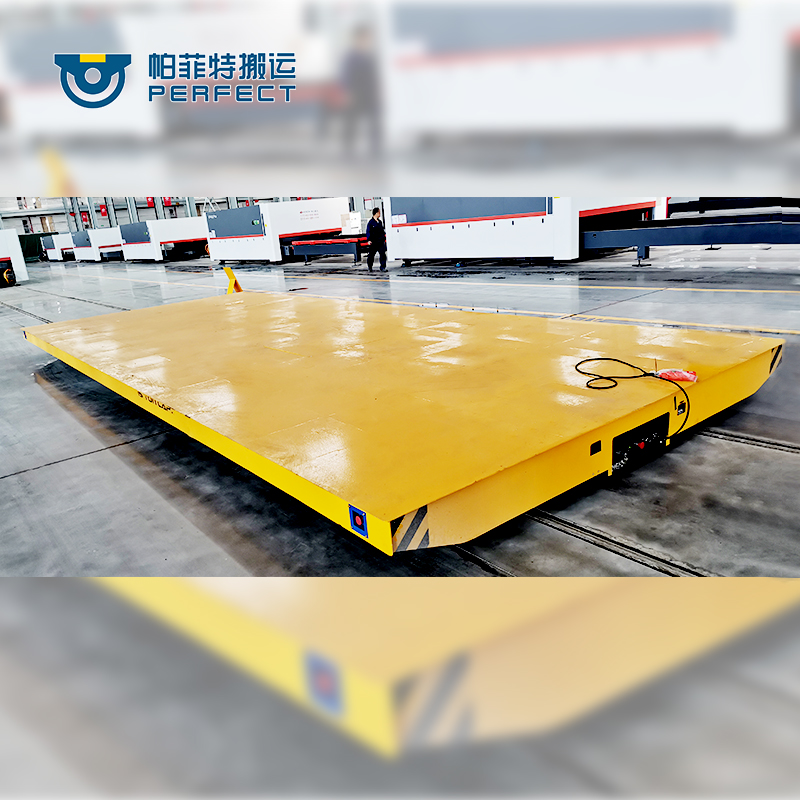

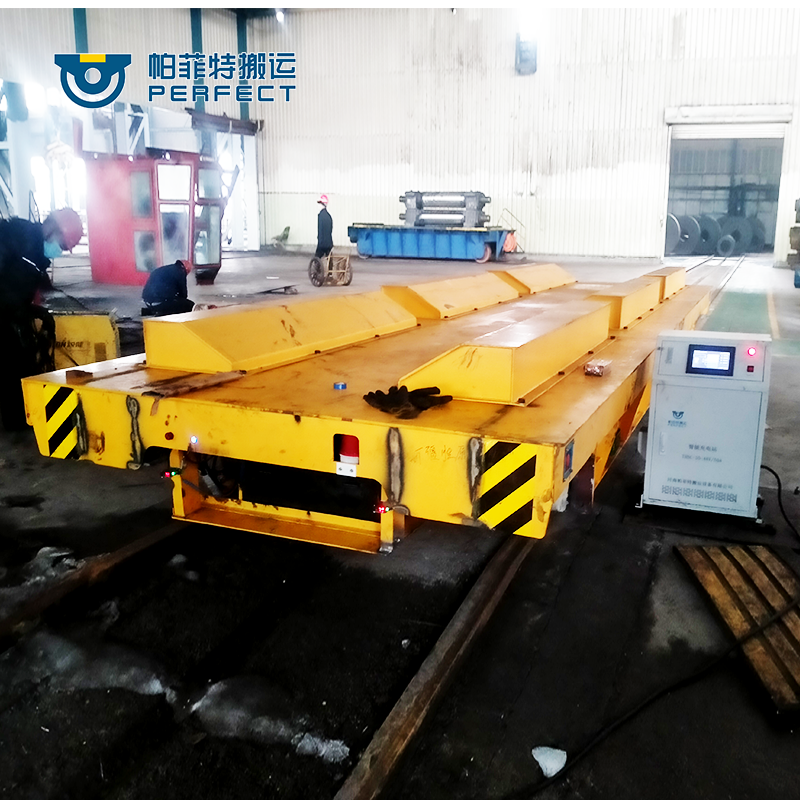

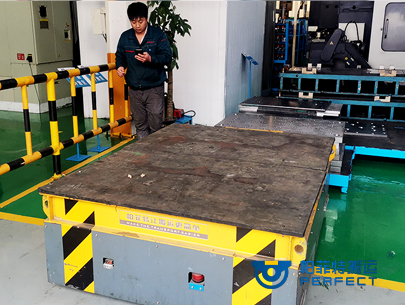

Usage:Heavy Duty Material Transportation

Application:Steel Industry, Factory, Warehouse, Port

Brand:Perfect

Load Capacity:1-300 Ton

Special Function:Anti-Explosion, Heat-Resistant, Lifting

Control Mode:Pendant/Remote/PLC Control

Power Mode:Battery/cable powered/rail powered….

Color:Customzied

Trademark:PERFECT

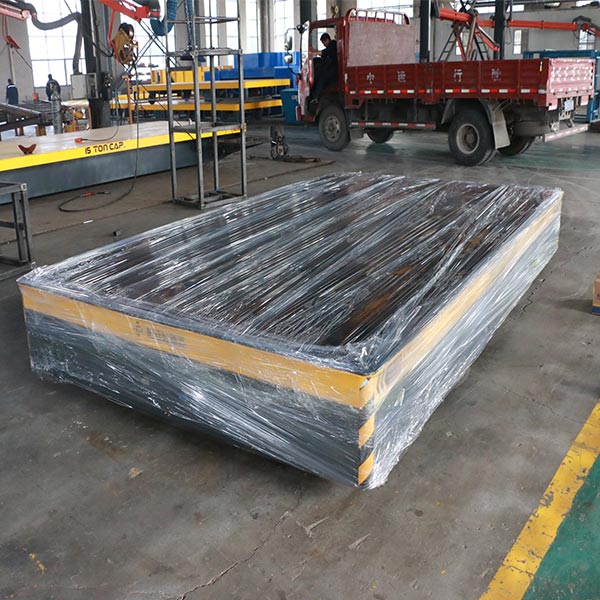

Transport Package:The Whole Cart Will Be Packed by Tarp.

Specification:Customized

Reasons and Elimination of Pump Shaft Vibration and Noise of High Quality Low Voltage Power Supply Rail Carrier

①The connection between the high-quality low-voltage power supply rail truck pump and the coupling will generate vibration and noise. Couplings should be adjusted as needed.

②Dust in the low-voltage powered rail truck oil entering the pump causes gears and other components to wear out, resulting in noise. Change the oil, strengthen the filter, disassemble the pump for cleaning. Seriously worn gears must be repaired or replaced.

③ When the parts in the pump are damaged or severely worn, vibration and noise will be generated in the low-voltage power supply rail truck: such as large tooth profile error or circumferential pitch error, poor contact between the two gears, high tooth surface roughness, and excessive normal normal length tolerance , the tooth surface clearance is too small, and the contact area of the two meshing gears is not at the position of the index circle. At this point, the gears or mating gears can be replaced. At the same time, the damaged needle roller cage, long journal and short journal, and the needle roller wear of the bearing will cause mechanical noise caused by poor bearing rotation. In this case, the gear pump needs to be disassembled and the needle bearing replaced.

.jpg)