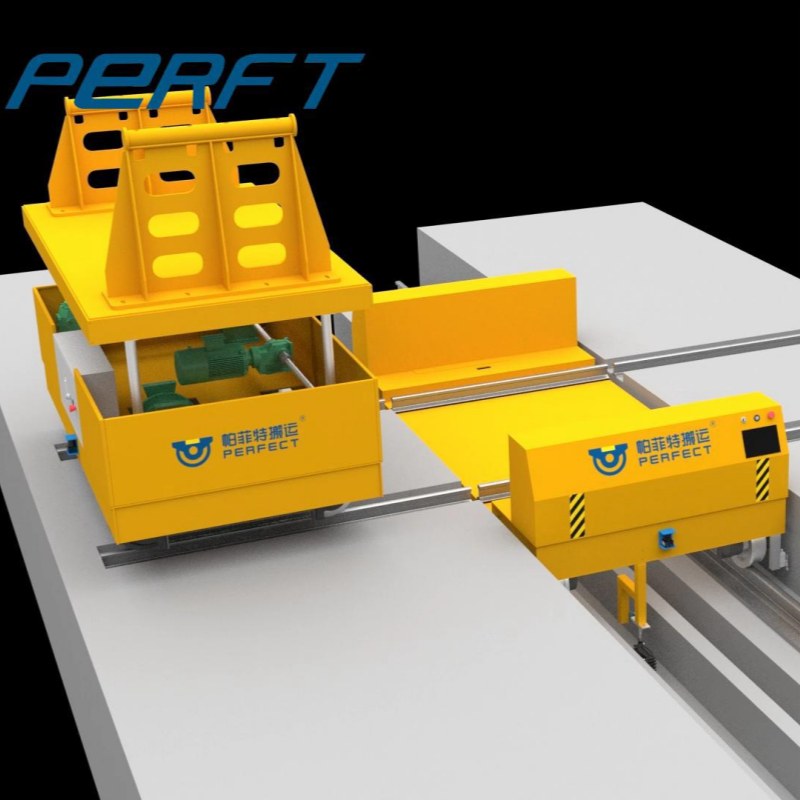

Low pressure electric transfer trolley–material transfer cart

low voltage electric transfer trolley adopts the steel rail as the sliding contact line to transmit the low voltage safety voltage. The steel rail is not only the running track of the wheel, but also the feed track.

Electric Transfer Cart-Perfect

Heavy load electric transfer cart is made up of the battery as the power source of the series of flat cars. It supplies power to the flat car,The DC current flows into the electric box, and the electric box is supplied to the operating system and the motor. The control unit or the remote control controls the motor. Reverse, stop, etc., and then control the forward, backward, start, and stop of the transfer cart.

Electric motorized material transfer carts on rail is suitable for various use environments, and can work in indoor, outdoor, inflammable and explosive environments, and can also add hydraulic devices, buffer devices, etc. on the flat car. The operation is simple. When the transportation distance is long, the on-board operation console can be added to the transfer cart to meet the long-distance transportation of the customer and realize the humanized design.

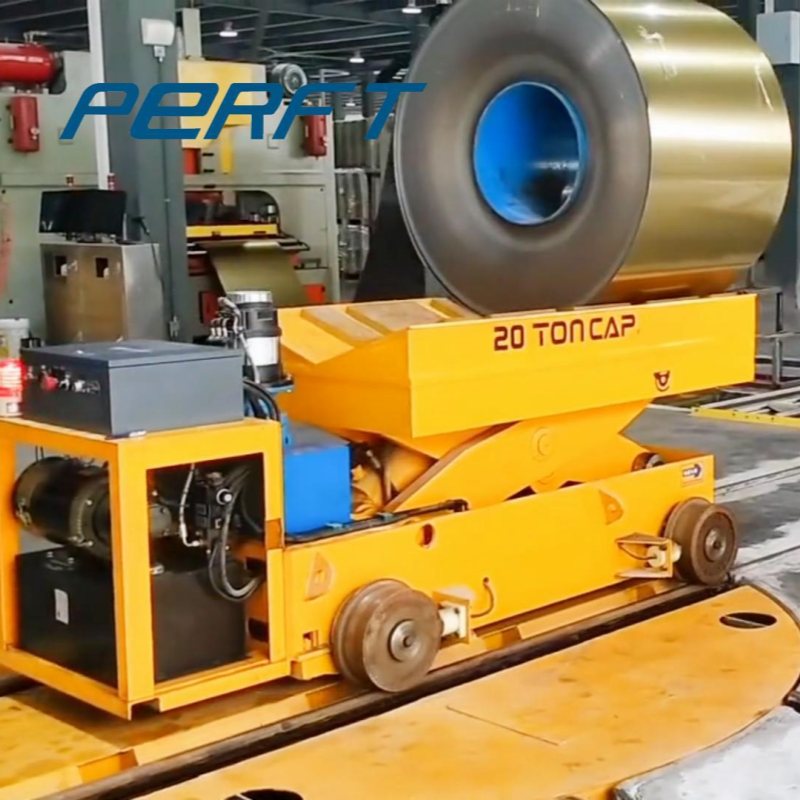

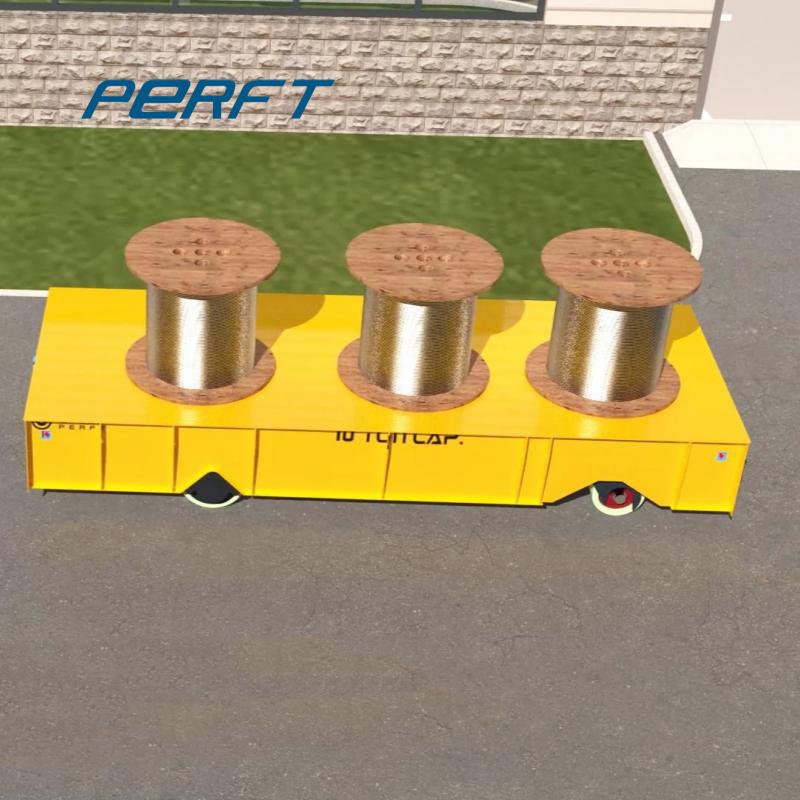

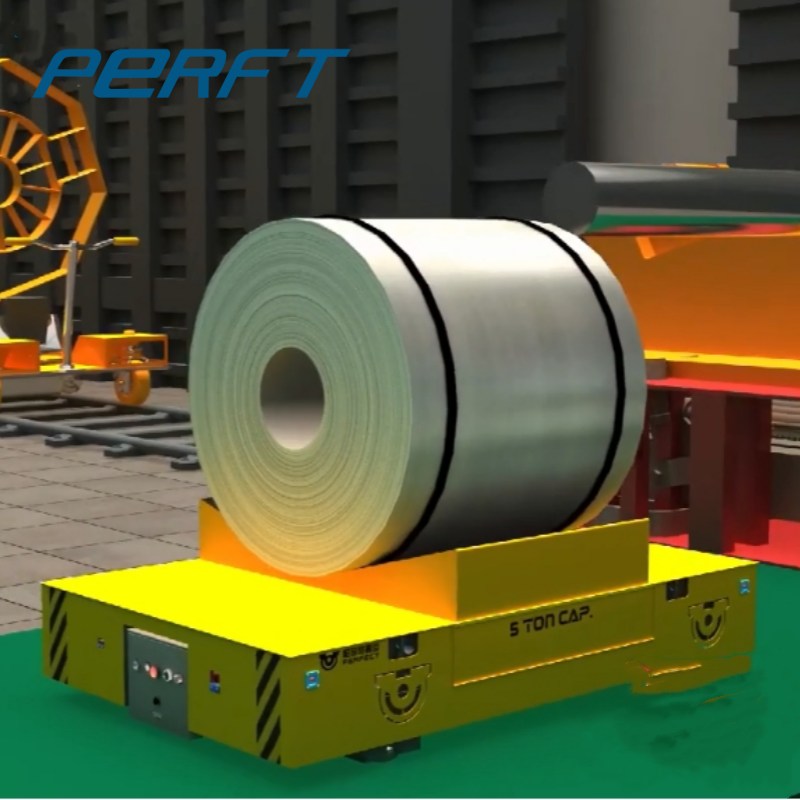

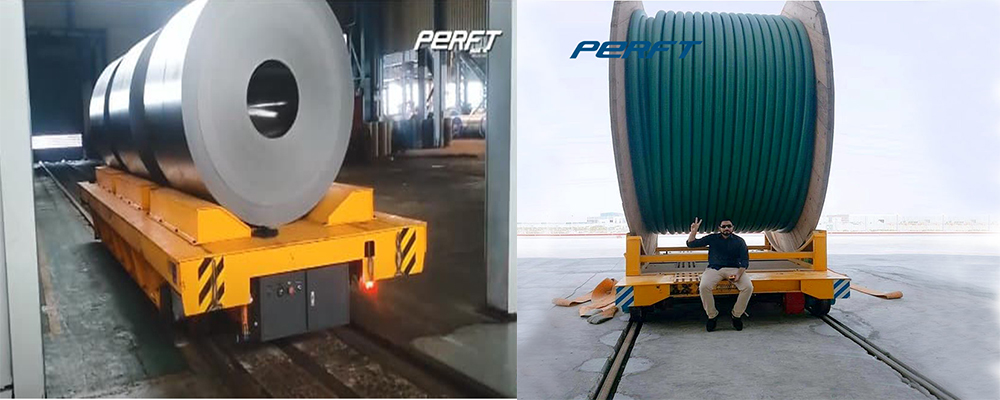

Electric transfer cart to handling steel coils

Coil car (also referred to as “steel coil cars” or “coil steel cars”) is a special type of rolling stock designed to transport sheet metal coils (i.e. coils) – steel coils, which are usually There is a V-shaped frame, because the steel coil is a cylinder and it is easy to fall, so there is a V-shaped frame.

- 1.The series powered coil rail car has the advantages of safety and flexibility, no distance restriction, adjustable speed, smooth start, large starting moment, small impact on reducer, low voltage, long service life and so on. The track laying requirements are not high, and are suitable for occasions with low frequency and long distance transportation.

- 2.DC motor is selected for powered coil rail car, which is suitable for frequent use and has higher safety and mobility. In order to meet the high frequency transportation environment, it can be equipped with a hard gear reducer, which makes the later maintenance of flat cars simpler.

- 3.The mechanism of this series of powered coil rail car is relatively simple, easy to repair, easy to disassemble and assemble, strong bearing capacity, long service life, low requirements for track laying, low cost, suitable for harsh environment, high temperature environment and other occasions.

- 4.The powered coil rail car are suitable for various use environments. They can work in indoor, outdoor, inflammable and explosive environments. They can also be equipped with hydraulic devices and buffer devices. Simple operation, in the case of long distance transportation,the flat car can add on-board operating platform to meet customer long-distance transportation and realize humanized design.

- 5.The powered coil rail car can add PLC control system, automatic rail car, greatly increase efficiency.

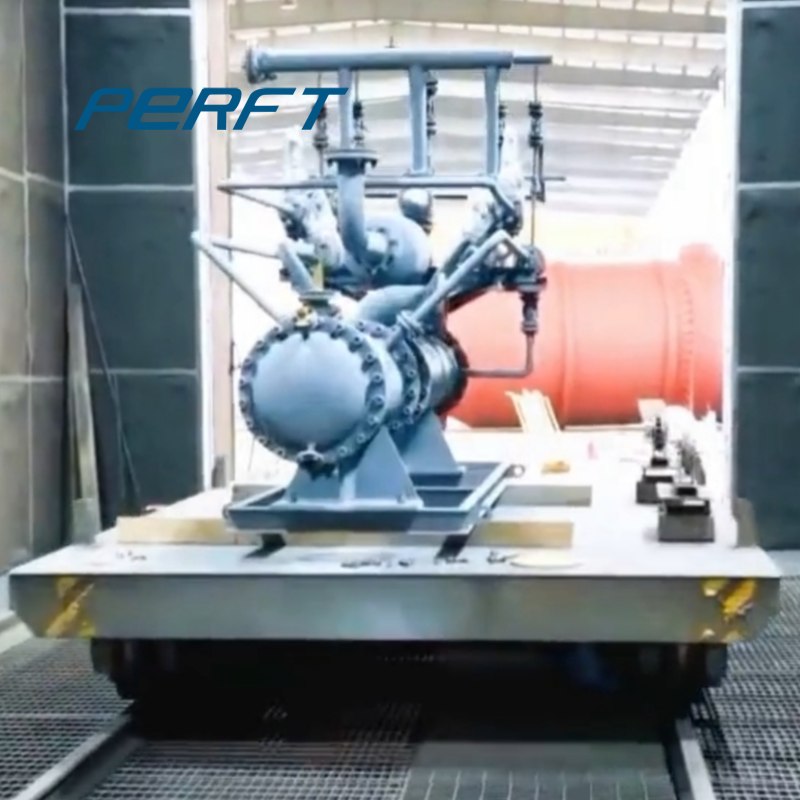

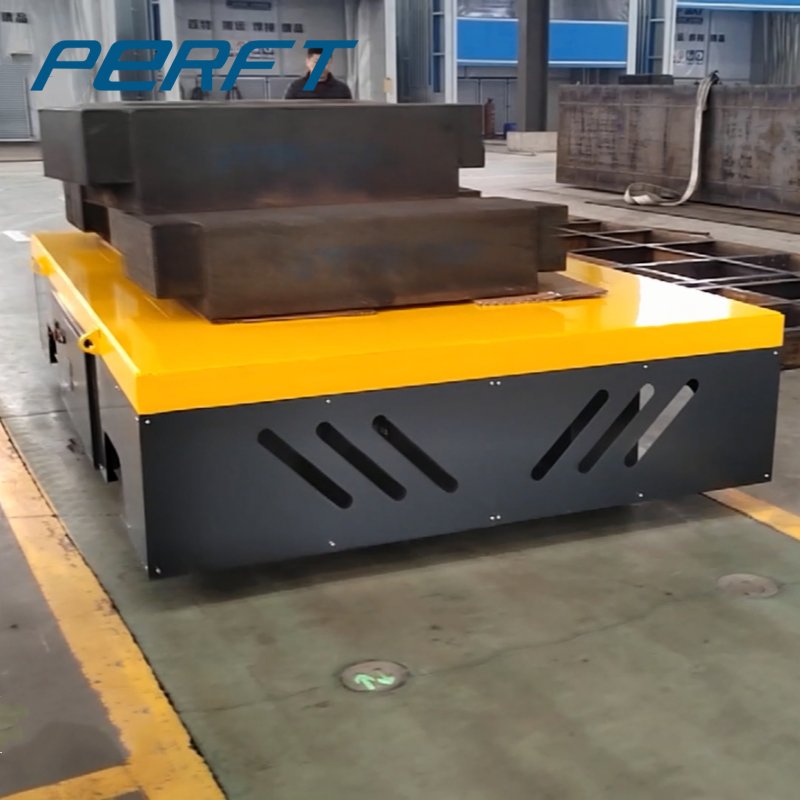

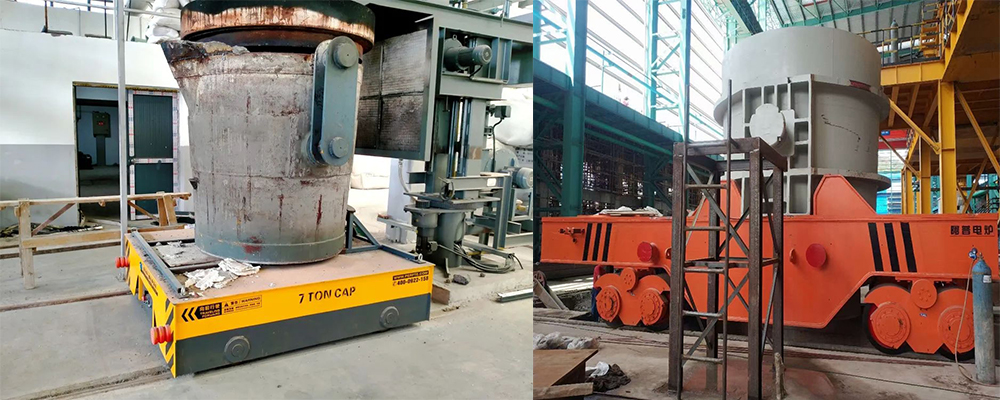

Electric transfer cart to handling heavy duty molds

Mold transfer cart for molds is designed for die and mold handling, it is an electric transport cart which can be powered by a battery, low voltage rail, cable drum, towed cable. There are two types of electric transfer carts, rail guided and trackless freely movable. Whether you opt for a rail-guided or a freely trackless movable solution, all can be met with a customized solution.

Applications of the injection molding tool carts :

- 1.Die handling;

- 2.Portable machine base;

- 3.Metal coil transporter;

- 4.Heavy equipment transporter with lift deck;

- 5.Structural steel transporter; S

- 6.huttle cart for the pipe;

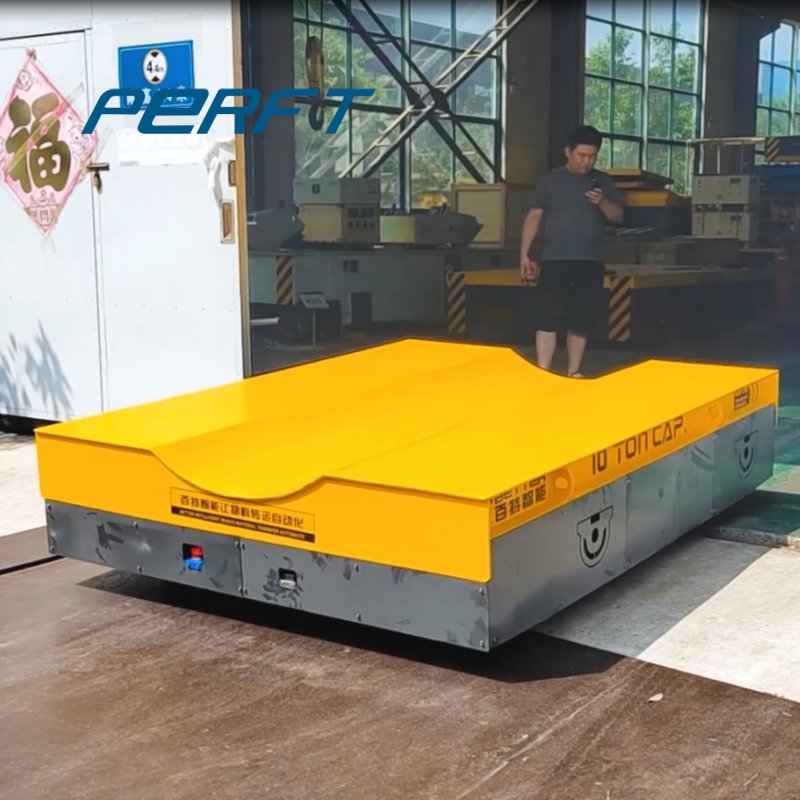

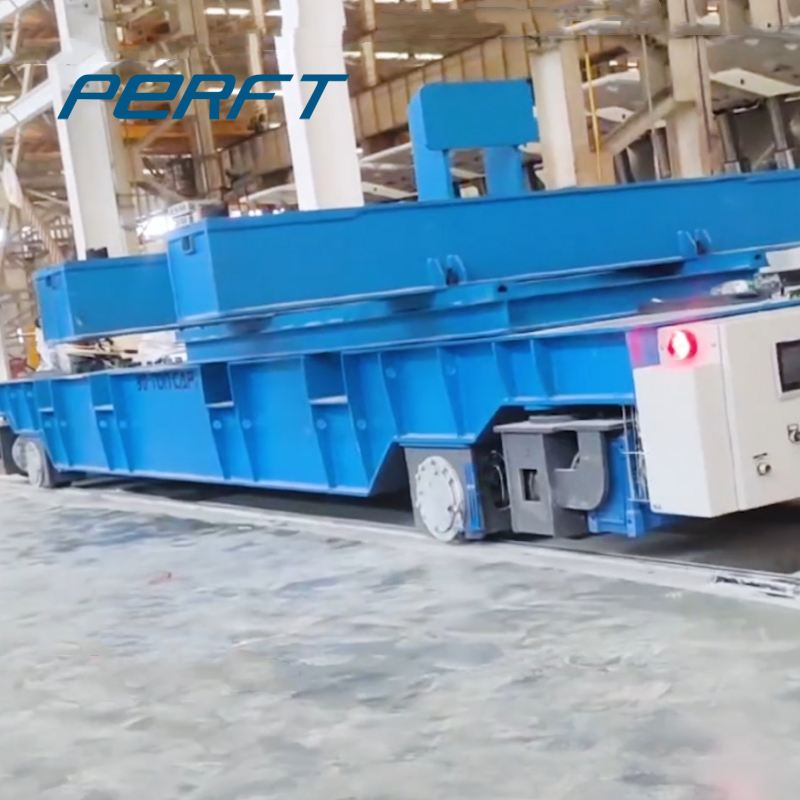

Electric transfer cart to handling ladle

Steel plant ladle transfer die bogie consisted of a power source, gear train, steel structure bearing frame, steering gear, running gear, control system, and fault diagnosis module to better the Electric Trackless Transfer cart.

Advantages and functions of the steel plant ladle transfer cart

- 1. The steel plant ladle transfer cart needn’t run via the rails, which gets rid of relying on the rails.

- 2. The steel plant ladle transfer cart cannot lead to impairment for the cement ground and can run freely, go forward, back forward, turning.etc.

- 3. The steel plant ladle transfer cart is battery powered, so only charged fully.

- 4. The steel plant ladle transfer cart can it run freely without limited distance.

- 5. The steel plant ladle transfer cart will be provided getting for your inquiry.

- 6. The steel plant ladle transfer cart are customized as per your true demand.

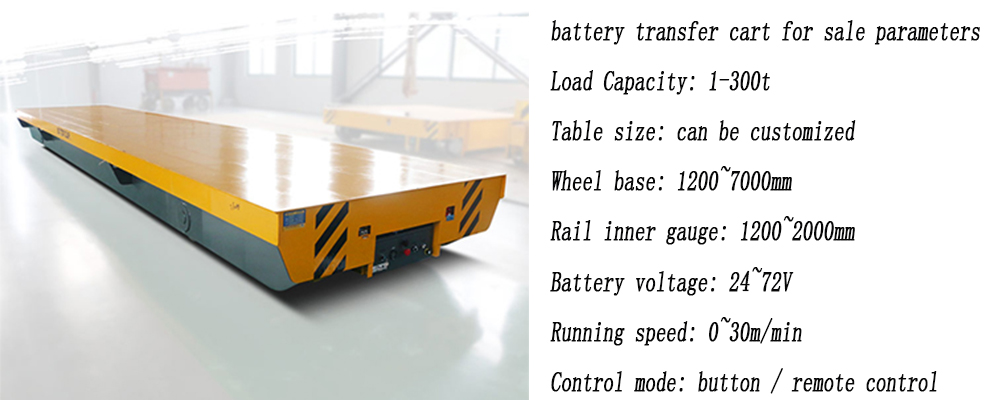

Technical Parameters Of Battery Transfer Cart

| Model | BXC-2T | BXC-10T | BXC-20T | BXC-30T | BXC-50T | BXC-63T | BXC-150T | |

| Rated load (T) | 2 | 10 | 20 | 30 | 50 | 63 | 150 | |

| Table size | length(L) | 2000 | 3600 | 4000 | 4500 | 5500 | 5600 | 10000 |

| Width(W) | 1500 | 2000 | 2200 | 2200 | 2500 | 2500 | 3000 | |

| Height(H) | 450 | 500 | 550 | 600 | 650 | 700 | 1200 | |

| Wheel Base (mm) | 1200 | 2600 | 2800 | 3200 | 4200 | 4300 | 7000 | |

| Wheel Diameter(mm) | Φ270 | Φ300 | Φ350 | Φ400 | Φ500 | Φ600 | Φ600 | |

| Ground Clearance (mm) | 50 | 50 | 50 | 50 | 50 | 75 | 75 | |

| Motor Power (Kw) | 1 | 1.6 | 2.2 | 3.5 | 5 | 6.3 | 15 | |

| Battery Capacity(Ah) | 180 | 160 | 180 | 250 | 330 | 400 | 600 | |

| Battery Voltage(V) | 24 | 48 | 48 | 48 | 48 | 48 | 72 | |

| Running Time When Full Load | 4.32 | 4.8 | 4 | 3.5 | 3.3 | 3 | 2.9 | |

| Running Distance for one Charge(Km) | 6.5 | 7.2 | 4.8 | 4.2 | 4 | 3.6 | 3.2 | |

| Max Wheel Load (KN) | 14.4 | 42.6 | 77.7 | 110.4 | 174 | 221.4 | 265.2 | |

How can Transfer Carts be customized?

Please tell us:

- 1.What load or product will be transferred onto the cart?

- 2.What is the weight of the heaviest lift or load?

- 3.What are the dimensions? (Length; Width ; Height)

- 4.What is the trip time and frequency? (# of Trips per , Shifts per day:)

- 5.What is the travel area you need to cover? (Rail/cement floor, Indoor/Outdoor, straight line travel, etc)

- 6.What is the distance to travel?

- 7.Other relevant information or using condition.